Modern labeling is generally regarded as having begun around the turn of the 18th century with the labeling of containers for medicine. Labeling has come a long way since those early days, and today we live in an age of regulated labeling. Consistency, accuracy and – above all – labeling compliance with regulations are not choices, they are imperatives.

What is labeling compliance?

If a label is compliant, it meets the regulatory standards for that product, such as Current Good Manufacturing Practices (CGMPs). But we can also go one step further and talk about compliance with recommended or perhaps voluntary standards for some goods, such as some ISO standards in fast moving consumer goods (FMCG) and food sectors. Either way, non-compliance with required or generally accepted quality standards can have far-reaching consequences.

Why labeling compliance is important

In the broadest sense, labeling compliance is important because it helps those consuming or administering a product to identify and understand the product, and to subsequently make informed decisions. For example, a Nutrition Facts label in the European Union shows energy, fat, saturated fat, carbohydrates, sugars and salt. But the label might also contain helpful additional voluntary information.

Safety is another important factor, especially for packaging and labeling of medicines, medical devices and food products. When it comes to food products, most of us will have seen the “May contain traces of” or “Contains traces of” warnings on product labeling. This helps consumers make informed choices on safety in regard to allergies or intolerances.

Compliant labeling helps guarantee authenticity

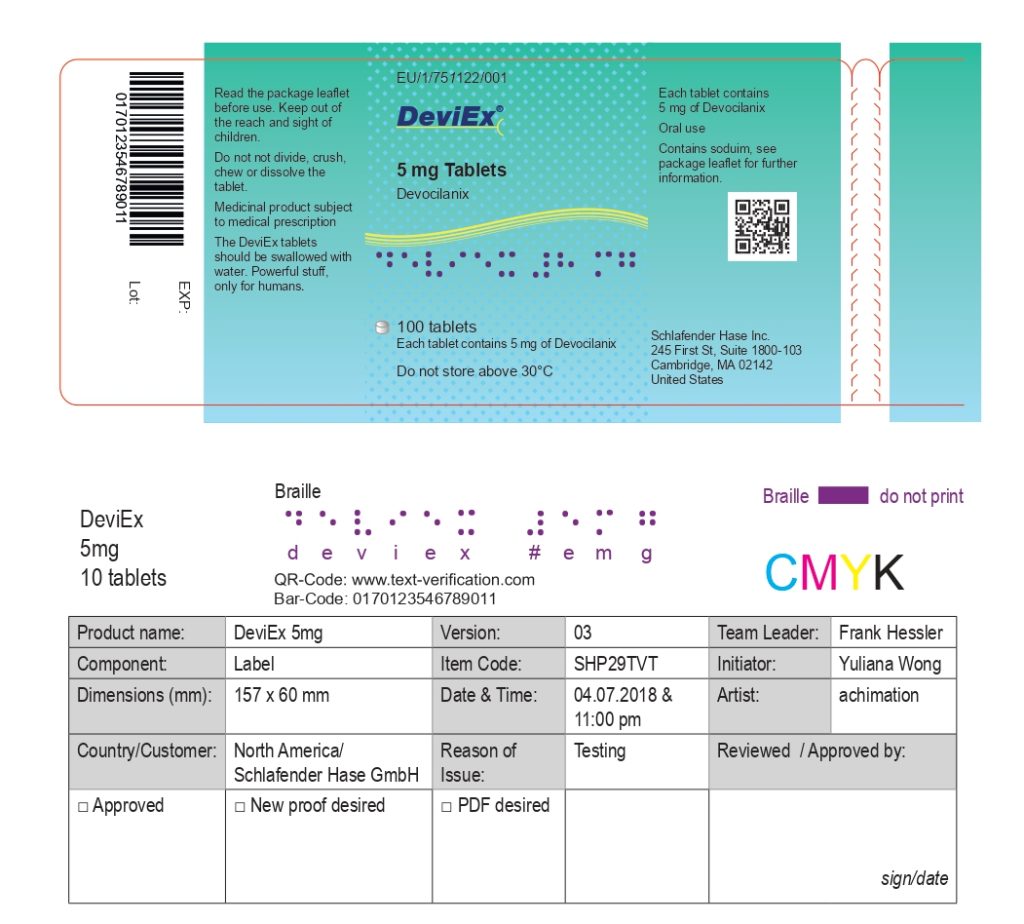

Safety is also the primary concern when it comes to fighting counterfeit drugs, which is why companies label products with unique identifiers, barcodes and with information about the manufacturers. In this case, complying with regulatory standards and industry standards serves the goal of guaranteeing authenticity.

Counterfeit medicines, particularly with the rise of international online stores, are a significant problem today, with estimates that the global counterfeit market is around US$ 200 to 432 billion, and that makes “pharmaceuticals the number one illicit activity, ahead of other underground economic activities such as prostitution, human trafficking, marijuana, electronics, and arms sales.”

But of course, counterfeiting is not limited to medicines, as major consumer goods brands will tell you. Some goods manufacturers use tracking and tracing technologies, including QR codes and digital watermarks, to protect their brands. The US Food and Drug Administration (FDA) requires barcodes for specific human and biological products as an aid to identification and use, helping to ensure that patients receive the proper drug treatment. Unique device identification barcodes and Human Readable Interpretation (HRI) are required for certain medical devices.

Compliant labeling saves money

Compliant labeling helps ensure health and safety, but it also reduces financial loss due to recalls, and damage to brand image. If labeling is for a product that undergoes rigorous approval processes (e.g. medicines), ensuring from the outset that labeling and packaging is compliant will save costs further down the track due to product recalls, delays, damage to brand and company reputation, and lost market share.

Understanding labeling regulations and standards

In order to achieve labeling compliance, it is important to understand the regulations. Fast moving consumer goods (FMCGs) in their different sectors, food, and pharmaceuticals are all subject to different or overlapping regulations. Food labeling in the US is regulated by the Food and Drug Administration (FDA).

In the European Union (EU), the European Medicines Agency (EMA) and national bodies regulate pharmaceutical products. Regulation (EU) No 1169/2011 lays down principles, requirements and responsibilities for food labeling in the EU. But member states may also require national measures on specifically justified grounds. Beyond the EU, countries have their own national requirements in their own languages for their different markets.

How to ensure your product has compliant labeling

- Have people and processes in place to manage knowledge of regulations and standards. This should be coupled with the ability to manage workflows for labeling compliance in multiple languages right across the organization.

- Those responsible downstream for labeling compliance, such as regulatory affairs (RA) professionals in pharma or medical devices sectors, require tools to ensure accuracy, achieve the level of efficiency and productivity for coping with high workloads, and reduce the risk of labeling non-compliance due to human error.

TVT, Proofreading Software for Regulated Industries, and its add-on modules TVT Artwork, TVT Spelling and TVT Barcode have been specifically designed to verify labeling and packaging in regulated environments. TVT is integrated into workflows in the pharmaceutical, medical devices, food products and FMCG sectors to verify text, graphics elements, and barcodes.

What you can expect from TVT:

- High level of labeling compliance through automated proofreading

- Less stress when proofreading labeling and packaging

- Better quality control early in the process by eliminating risks stemming from manual proofreading

- Easy management of workflows in multiple language versions across subsidiaries

- Faster turnarounds, and documentation of all actions taken, resulting in greater accountability

- Flexibility to work in any format, any language, including Braille, and tools to verify artwork, barcodes and spelling

- Fast return on investment (ROI). Calculate your ROI here

If you would like to find out more about how TVT, our Text Verification Tool, can help ensure your labeling is compliant, contact us below.